Laser spot welding machines offer several advantages over traditional welding methods:

-

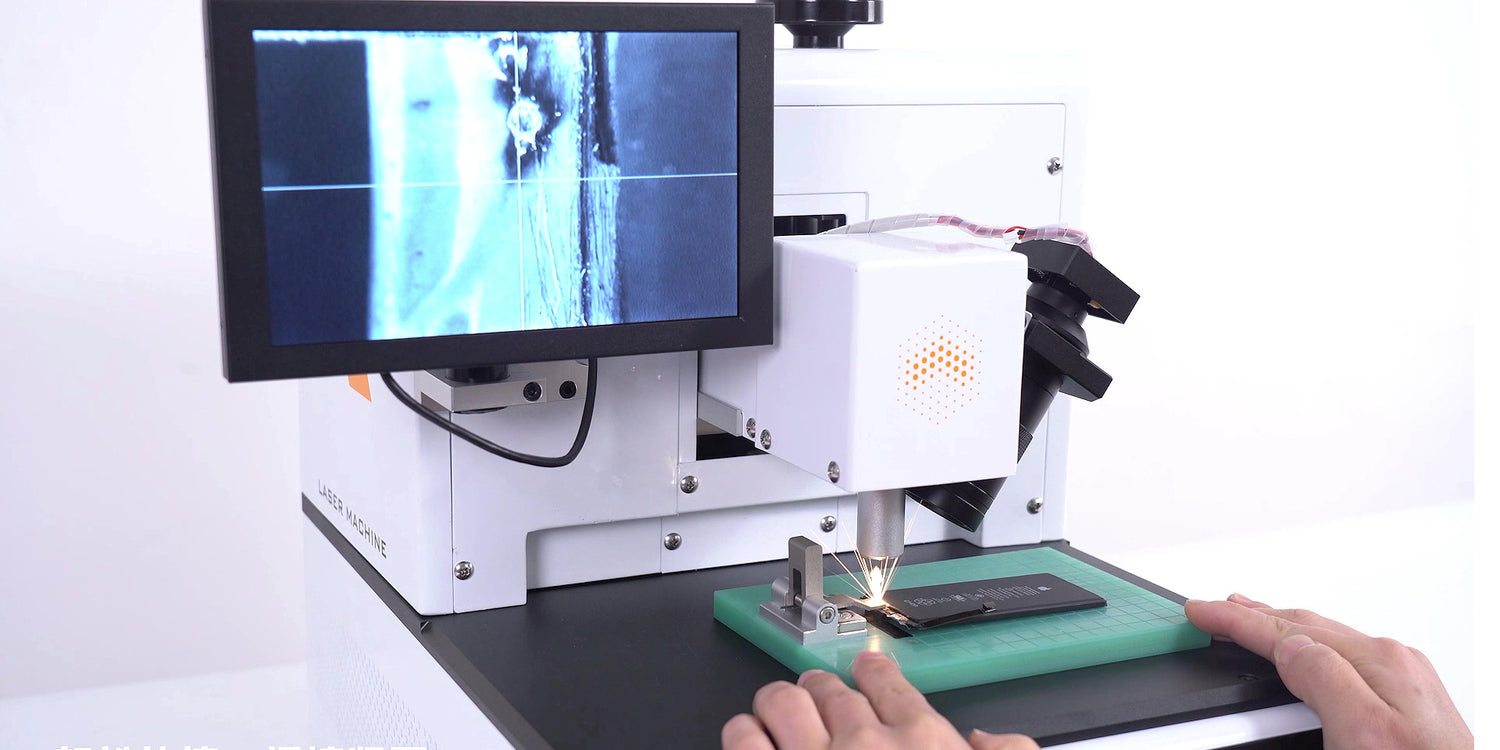

Precision: Laser spot welding allows for precise control over the welding process, enabling accurate positioning of the weld spot and minimizing the heat-affected zone. This precision is particularly beneficial for intricate or delicate workpieces.

-

High Speed: Laser welding is typically faster than traditional welding techniques. The concentrated energy of the laser beam enables rapid heating and melting of the materials, leading to shorter cycle times and increased productivity.

-

Minimal Distortion: Due to the localized heat input and precise control over the welding process, laser spot welding produces minimal distortion in the workpiece. This is especially advantageous for thin materials or components that are sensitive to warping.

-

Versatility: Laser spot welding machines can weld a wide range of materials, including metals, plastics, and composites. This versatility makes them suitable for various industries and applications, from automotive manufacturing to electronics assembly.

-

No Contact: Unlike traditional welding methods that require direct contact between the welding electrode and the workpiece, laser welding is a non-contact process. This reduces the risk of contamination and damage to the materials, leading to cleaner and more consistent welds.

-

Automation Integration: Laser spot welding machines can be easily integrated into automated production lines, allowing for seamless operation and increased efficiency. Robotic arms can be used to manipulate the workpieces and position them accurately for welding.

-

Energy Efficiency: Laser welding typically consumes less energy compared to traditional welding techniques. The focused beam of the laser minimizes heat loss and reduces the amount of energy required to complete the welding process.

-

Minimal Maintenance: Laser spot welding machines require minimal maintenance compared to traditional welding equipment. With fewer moving parts and less wear and tear, these machines offer increased reliability and uptime.

Overall, laser spot welding machines offer a combination of precision, speed, versatility, and efficiency that make them a preferred choice for many manufacturing applications.