MOPA laser marking machine applied to stainless steel color marking

When marking stainless steel materials, laser can change the color variation of the surface layer by adjusting the laser beam, thus achieving different decorative effects. In order to print colors on stainless steel, regular laser equipment cannot achieve this, but MOPA laser marking machine can.

There are three ways to achieve coloration on stainless steel: first, by generating oxides; second, by forming a very thin colorless transparent oxide film on the stainless steel surface through chemical, electrochemical, or laser action, which produces an interference effect and displays colors on the surface; third, by simultaneously having colored oxides and oxide film in a mixed state. The MOPA laser marking machine mainly changes the color of the material surface layer through the energy of the laser beam, resulting in a colorful decorative effect. The MOPA laser marking machine adds wide and narrow pulses on the basis of a standard laser machine, using different pulses to achieve multi-color functionality during material processing. The wide and narrow pulses of the laser can be independently controlled, with laser characteristics and good pulse shape control ability. It can be used for stainless steel color marking, blackening of oxidized aluminum, engraving on plastic and metal, and stripping paint from reflective mirrors, among other functions.

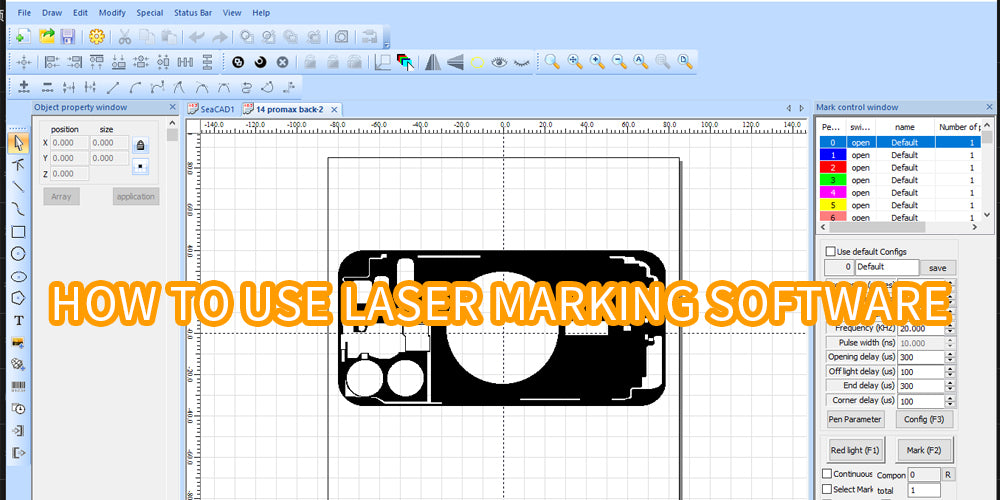

MOPA laser marking machine has fast marking speed and clear marking effect. Using a computer, you can freely adjust the marking height, text or pattern, and realize the free marking content. No chemical coloring, environmental protection, to avoid the production of toxic and harmful substances. Non-contact processing, no consumables, not easy to wipe.

When marking stainless steel materials, laser can change the color variation of the surface layer by adjusting the laser beam, thus achieving different decorative effects. In order to print colors on stainless steel, regular laser equipment cannot achieve this, but MOPA laser marking machine can.

There are three ways to achieve coloration on stainless steel: first, by generating oxides; second, by forming a very thin colorless transparent oxide film on the stainless steel surface through chemical, electrochemical, or laser action, which produces an interference effect and displays colors on the surface; third, by simultaneously having colored oxides and oxide film in a mixed state. The MOPA laser marking machine mainly changes the color of the material surface layer through the energy of the laser beam, resulting in a colorful decorative effect. The MOPA laser marking machine adds wide and narrow pulses on the basis of a standard laser machine, using different pulses to achieve multi-color functionality during material processing. The wide and narrow pulses of the laser can be independently controlled, with laser characteristics and good pulse shape control ability. It can be used for stainless steel color marking, blackening of oxidized aluminum, engraving on plastic and metal, and stripping paint from reflective mirrors, among other functions.

MOPA laser marking machine has fast marking speed and clear marking effect. Using a computer, you can freely adjust the marking height, text or pattern, and realize the free marking content. No chemical coloring, environmental protection, to avoid the production of toxic and harmful substances. Non-contact processing, no consumables, not easy to wipe.