In the competitive world of smartphone repair, the installation of screen protectors is a common yet crucial task. Ensuring that these protectors are applied without air bubbles is essential for both the aesthetic and functional integrity of the device. While manual methods can be effective, utilizing a Bubble Remover Machine streamlines the process, making it faster and more efficient. This guide is designed for mobile repair entrepreneurs and technicians looking to master the use of a bubble remover machine for flawless screen protector application.

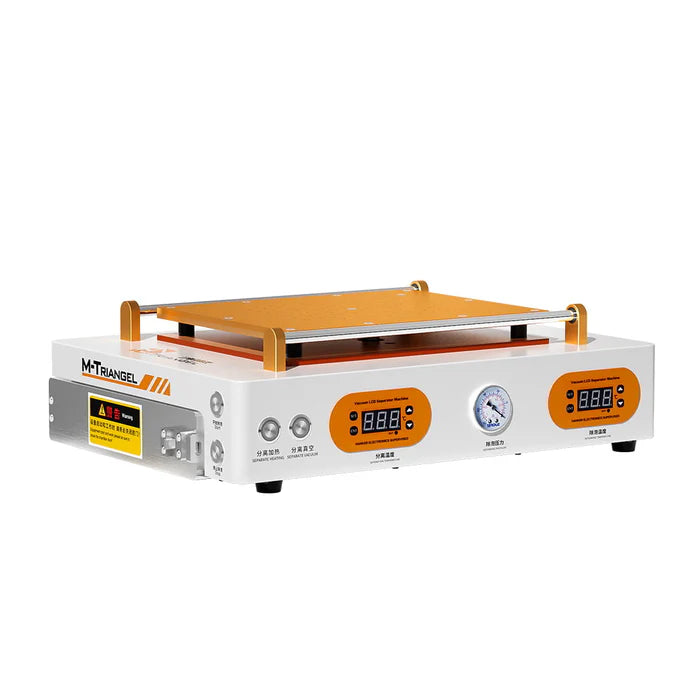

MT-103 OCA Vacuum Laminating Bubble Remove Machine 5-in-1

Understanding Air Bubbles

Air bubbles can form beneath screen protectors for several reasons:

- Dust and Debris: Even the smallest particles can prevent the adhesive from bonding properly.

- Improper Alignment: Misalignment during the installation can trap air.

- Temperature Variations: Fluctuations in temperature can cause the adhesive to behave inconsistently.

Understanding the causes of air bubbles can help you prevent them and effectively remove them when they occur.

Benefits of Using a Bubble Remover Machine

1. Efficiency

A bubble remover machine significantly reduces the time spent on bubble removal. Instead of manually pushing out bubbles, the machine automates the process, allowing for quicker service.

2. Consistent Results

Using a machine ensures a more uniform application of pressure, which can lead to more consistent results. This minimizes the risk of damaging the screen protector or the device.

3. Reduced Risk of Damage

Manual methods can sometimes lead to scratches or further misalignment. A bubble remover machine minimizes physical contact with the screen, reducing the risk of accidental damage.

How to Use a Bubble Remover Machine

Step 1: Prepare the Device and Screen Protector

-

Clean the Screen: Use a microfiber cloth and an appropriate screen cleaner to thoroughly clean the device’s screen. Make sure no dust or fingerprints remain.

-

Align the Screen Protector: Carefully align the screen protector over the device. Ensure it is positioned correctly before applying pressure.

Step 2: Set Up the Bubble Remover Machine

-

Power On the Machine: Turn on the bubble remover machine and allow it to reach the required operating temperature. Refer to the machine’s manual for specific instructions on optimal settings.

-

Adjust the Vacuum Settings: Depending on the machine, adjust the vacuum pressure to ensure it securely holds the device in place without causing damage.

Step 3: Apply the Bubble Remover Machine

-

Position the Device: Place the device in the bubble remover machine, ensuring it is centered and aligned correctly.

-

Engage the Vacuum: Activate the vacuum function to hold the device securely in place.

-

Apply Heat (if applicable): If your machine includes a heating element, activate it to soften the adhesive, making it easier to remove any bubbles.

Step 4: Remove Air Bubbles

-

Monitor the Process: As the machine operates, observe for any air bubbles that may still be present. The combination of heat and vacuum will help in eliminating these.

-

Adjust if Necessary: If bubbles persist, you may need to adjust the pressure or heat settings slightly, allowing the machine to work more effectively.

-

Repeat if Needed: If some bubbles remain after the initial cycle, repeat the process for a short period until they are eliminated.

Step 5: Final Check

-

Inspect the Protector: After using the machine, carefully inspect the screen protector for any remaining bubbles.

-

Check Touch Sensitivity: Ensure that the screen is responsive and that the installation is flawless.

-

Clean the Edges: Wipe down the edges of the screen protector to remove any residue or dust that may have accumulated during the process.

Troubleshooting Common Issues

1. Persistent Air Bubbles

If air bubbles remain after using the bubble remover machine, it may indicate:

-

Improper Adhesive Quality: Consider the quality of the screen protector used. Low-quality protectors may not adhere properly, leading to persistent bubbles.

-

Incorrect Installation: Ensure that the screen protector was aligned correctly before activating the machine.

2. Screen Damage

If the screen gets damaged during the bubble removal process, check:

-

Pressure Settings: Ensure the pressure settings are appropriate for the device type.

-

Operator Technique: Make sure you’re following proper procedures to avoid applying excessive force.

3. Machine Malfunctions

If the bubble remover machine does not seem to be working effectively:

-

Check the Power Supply: Ensure the machine is plugged in and functioning properly.

-

Inspect for Blockages: Make sure there are no obstructions in the vacuum or heating elements.

Best Practices for Using a Bubble Remover Machine

-

Regular Maintenance: Keep the machine clean and well-maintained to ensure optimal performance.

-

Follow Manufacturer Instructions: Always adhere to the guidelines provided by the manufacturer for best results.

-

Training: Invest time in training technicians on the proper use of the machine to minimize errors and maximize efficiency.

Conclusion

Using a Bubble Remover Machine to eliminate air bubbles from screen protectors is an effective strategy for mobile repair technicians. By following the steps outlined in this guide, you can ensure a high-quality installation that enhances customer satisfaction. With practice, you’ll become proficient in using this valuable tool, leading to quicker repairs and happier clients. Welcome to check out M-Triange’s bubble remover machines. There are a variety of devices that you can choose to buy according to your needs. If you have any questions, please feel free to consult our experts.

In the process of repairing your mobile phone, you will also need to use an LCD separator machine. If you are not familiar with how to operate it, you can click to view the LCD screen separator operation guide.

Investing in a bubble remover machine is a smart move for any mobile repair business, making your workflow smoother and more efficient. Happy repairing!