Metal can be integrated into the marking elements, factories use laser process to engrave beautiful patterns on the metal surface to enhance the product quality of metal in the details. How does the laser process achieve the marking engraving on the metal surface?

The principle of laser marking on metal surface?

Fiber laser marking machine is usually used to achieve the engraving of patterns on metal surfaces. The use of high-energy laser beam irradiation to the metal surface to produce the burning trace principle, to achieve product information, logo, pattern engraving mark. Simply import the pattern information into the computer, and the computer-controlled equipment can efficiently complete the marking. Complex patterns can be easily completed.

Fiber laser marking machine process advantages?

Compared with the traditional printing and inkjet technology, laser marking is faster and more efficient, and the marking effect is clear and beautiful. Laser marking process is resistant to corrosion and wear, and the pattern can be retained for a long time. And the process application cost is low, safe and environmentally friendly, fast and efficient.

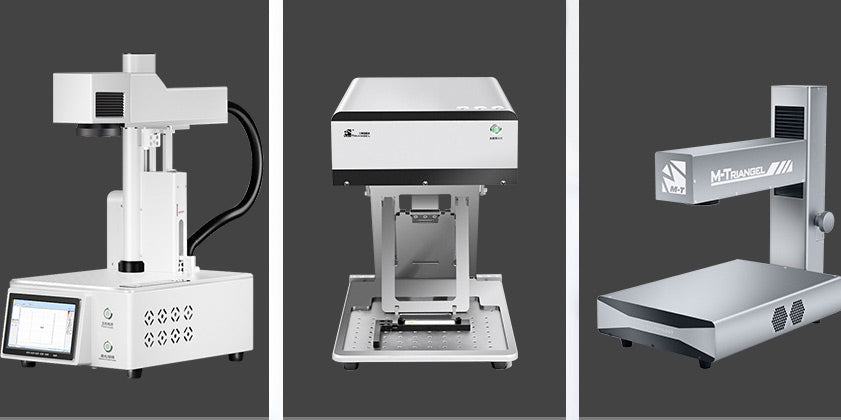

M-Triangel Fiber Laser Marking Machine

Parameter characteristics

- Marking accuracy: ≤0.001 mm

- Repeat accuracy: ≤0.001 mm

- Marking speed: ≤10000 mm/s

- Marking depth: 0.015~0.5 mm

- Marking format: 175 mm*175 mm

- Cooling method: built-in air cooling

- Laser wavelength: 1.06 um

- Marking line width: 0.05~0.01 mm

Model features.

1. Configure 100*100~175*175 mm multiple marking area to meet different marking range requirements

2. Configured with high-quality fiber laser, stable light source, long life

3. Can meet the marking of a variety of materials on the metal surface, such as: carbon steel, stainless steel, aluminum oxide, etc.